Get the most reliable encapsulation technology for N-type modules with DAS Solar

2023-10-28

The rising demand for clean energy has positioned solar photovoltaic technology as the predominant choice within the energy sector. For different technical modules, why are N-type modules pivotal in the photovoltaic industry, and why does POE film stand out as the optimal encapsulation material for N-type modules?

According to the Selective Emitter theory proposed by the Institute for Solar Energy Research in Hamelin (ISFH), maximum theoretical efficiency for N-type TOPCon cells is 28.7%, while for PERC cells it is 24.5%. As a leader in N-type technology, DAS Solar achieves an average production efficiency of 25.8% currently.

Choosing the right encapsulation material directly influences the durability and performance stability of modules when transforming solar photovoltaic cells into reliable photovoltaic modules.

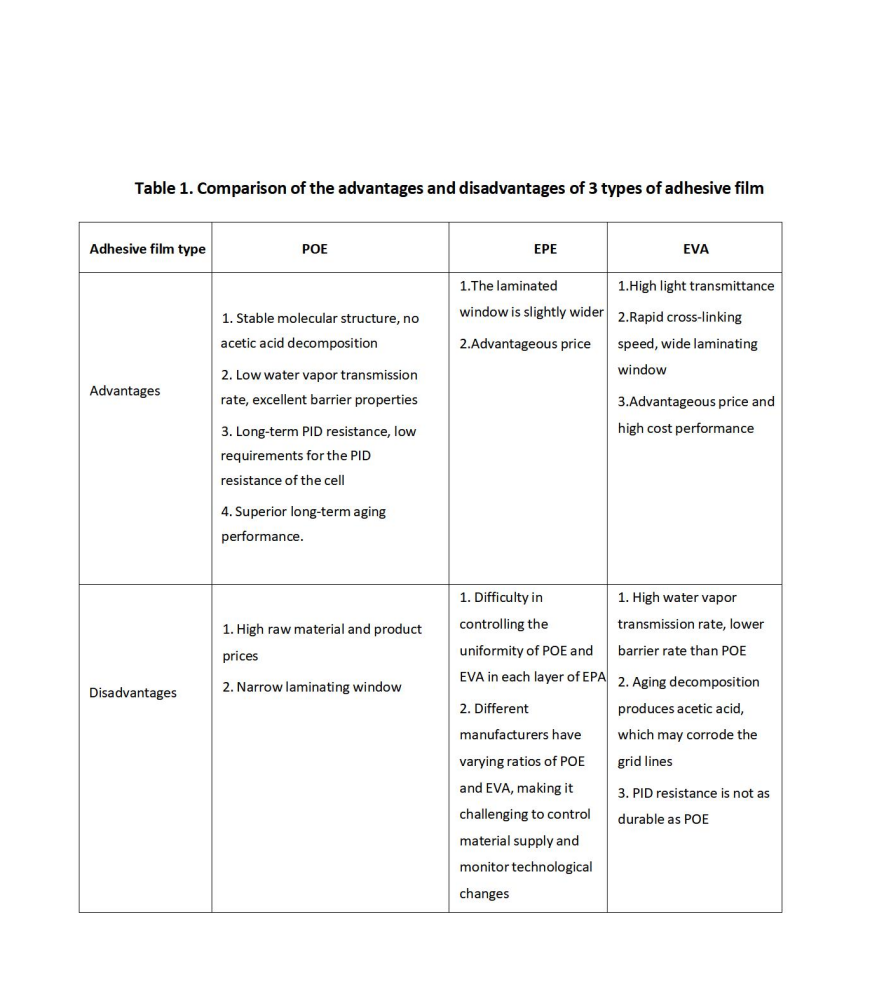

The mainstream N-type TOPCon modules are encapsulated in glass on both sides. The double glass structure inhibits water vapor permeation more effectively than single glass modules with polymer backsheets on the rear, protecting the cells within the module from moisture and other corrosive elements. Further, double glass modules offer a service life no less than 30 years, effectively ensuring the long-term reliable operation and outstanding power generation performance of PV plants. However, regarding encapsulation films, POE film exhibits superior performance when compared to EVA and EPE films.

POE film offers a wide range of advantages that make it the best choice for encapsulating N-type solar photovoltaic modules:

1. Sealability: POE film demonstrates outstanding sealability, effectively shielding against external moisture, dust, and other harmful substances, ensuring long-term stability within the solar cells.

2. Waterproof: PV modules are effectively protected from rain, humidity, and moisture with POE film's exceptional waterproofing capabilities.

3. Physical: POE film is highly resistant to heat and cold under various environmental conditions, making it suitable for a wide range of temperatures and weather.

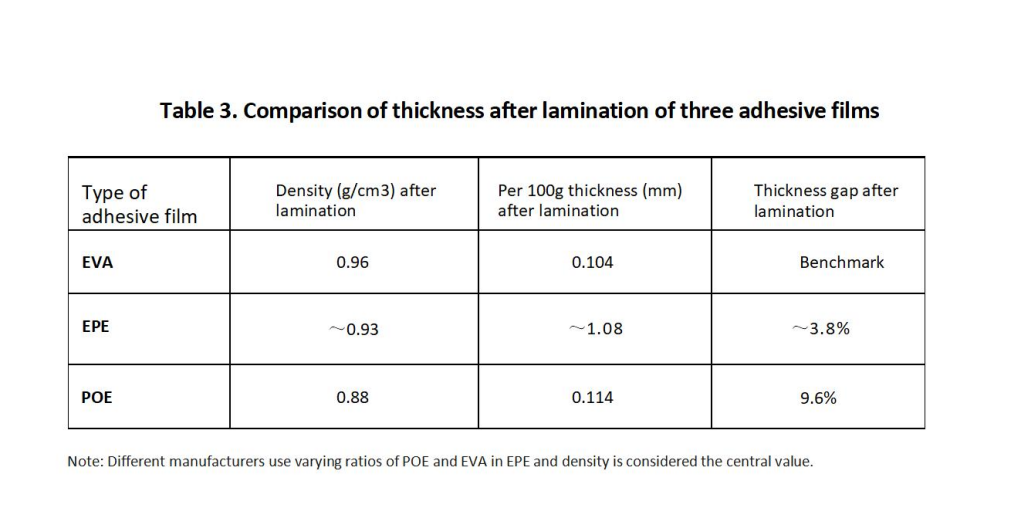

4. Thickness & Gram weight: POE film can be customized to meet specific requirements, offering greater thickness and reduced gram weight, which helps to reduce the weight of the module.

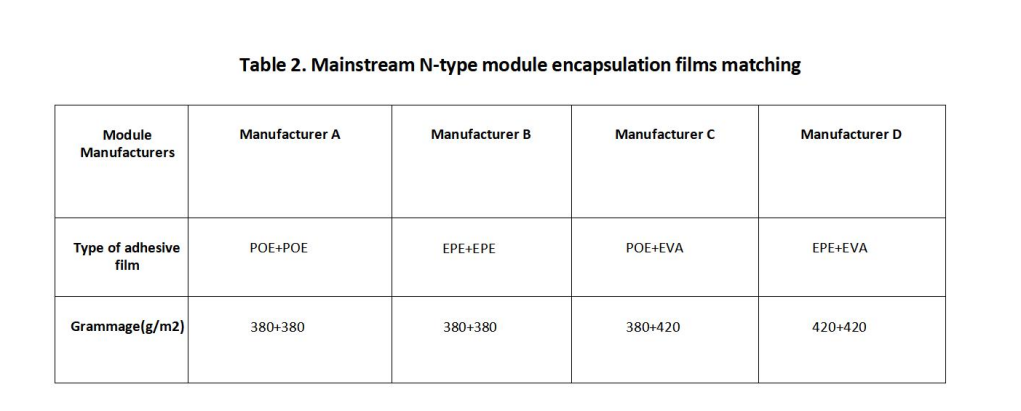

In an effort to reduce costs, various manufacturers of N-type TOPCon modules use different encapsulation films. These disparities in encapsulation films also pose a risk to their long-term reliability.

Various structural and material techniques have been used to encapsulate N-type modules, but the only combination that has demonstrated reliable long-term performance is 'POE + POE'. The model of 'POE + POE' effectively addresses the challenges of module applications in extreme climatic conditions, ensuring long-term stable output for PV plants and delivering maximum value to customers.

Based on an extensive comparison of encapsulation film combinations for N-type modules, POE offers distinct advantages, particularly in the following aspects:

1. As POE film is thicker than EVA and EPE, it protects solar cells better against stress impact and ensures module performance.

2. Featuring high volume resistivity and outstanding damp-heat resistance, POE modules exhibit robust and stable PID resistance.

3. Modules encapsulated with POE film exhibit a stabilized power degradation trend after DH, PID and TC testing, enabling them to better harness their power generation potential.

China Photovoltaic Industry Association estimates that the market share for N-type solar cells will exceed 20% in 2023 and 50% by 2025. The rise of N-type solar cells signifies progress and innovation within the photovoltaic industry. As cell efficiency continuously improves, module efficiency is also simultaneously improved. A comprehensive comparative analysis has revealed that POE encapsulant film is the best and most reliable encapsulant film for N-type modules due to its outstanding performance.

浙公网安备33080302000236

浙公网安备33080302000236