What is the best technical selection for photovoltaic modules?

2023-11-14

A gradual transition from P-type to N-type has begun since 2022. As N-type cells are fully implemented and module production capacity ramps up, N-type modules will gradually become mainstream. However, technological advances in materials are also progressing in parallel with advances in cell technology. As for photovoltaic film, it has a significant impact on the efficiency and lifespan of photovoltaic modules, despite making up just 5% of the photovoltaic industry chain. Module failures have increased in recent years. At the same time, the photovoltaic film industry is undergoing a technological transformation.

Encapsulation film stands as a pivotal material within the realm of photovoltaic modules. The quality and performance of the encapsulation film has a direct correlation with the failure of photovoltaic modules. This includes issues such as PID effects, film discoloration, delamination, and moisture-induced cell corrosion. In fact, photovoltaic film is an important encapsulation material with a profound impact on photovoltaic module quality and longevity. These modules' life span is determined by performance indicators such as light transmission, shrinkage rate, peel strength, and resistance to aging.

There is a certain degree of disparity among module manufacturers in terms of their production approaches, despite the widespread adoption of TOPCon N-type technology modules. For example, encapsulation solutions are prevalent in the current market in three primary categories: EVA, POE, and EPE. Despite exceptional encapsulation performance, resistance to aging, and cost-effectiveness, EVA has a high water vapor transmission rate. When EVA material undergoes hydrolysis, acetic acid is produced, which reacts with sodium (Na) in photovoltaic glass and corrodes the busbars, degrading module performance and increasing series resistance. POE encapsulation film demonstrates formidable resistance to water vapor and ion barrier capacity. Its molecular composition, free from acetic acid, low water permeability and high volume resistivity. In addition to its relatively higher price, it is prone to string distance offsets and bubble formation during lamination.

The EPE encapsulation film has the advantages of both EVA and POE. However, raw material still contains EVA in its raw materials. Consequently, it decomposes unavoidably into acetic acid when subjected to conditions involving thermal stress, heat oxidation, and high humidity. The efficiency of the cell can decrease as a result of corrosion on the surface of the cells and solder strips.

Due to the higher water vapor sensitivities of TOPCon's fine grid aluminum silver paste in N-type technology, encapsulation film water-blocking performance requirements are higher. The thinner cell wafers become more vulnerable to acidity and surface stress, making an encapsulation film more important. N-type cells have opposite PN junctions compared to P-type cells, making them more susceptible to PID on their front side. Consequently, encapsulation films need to exhibit greater PID resistance.

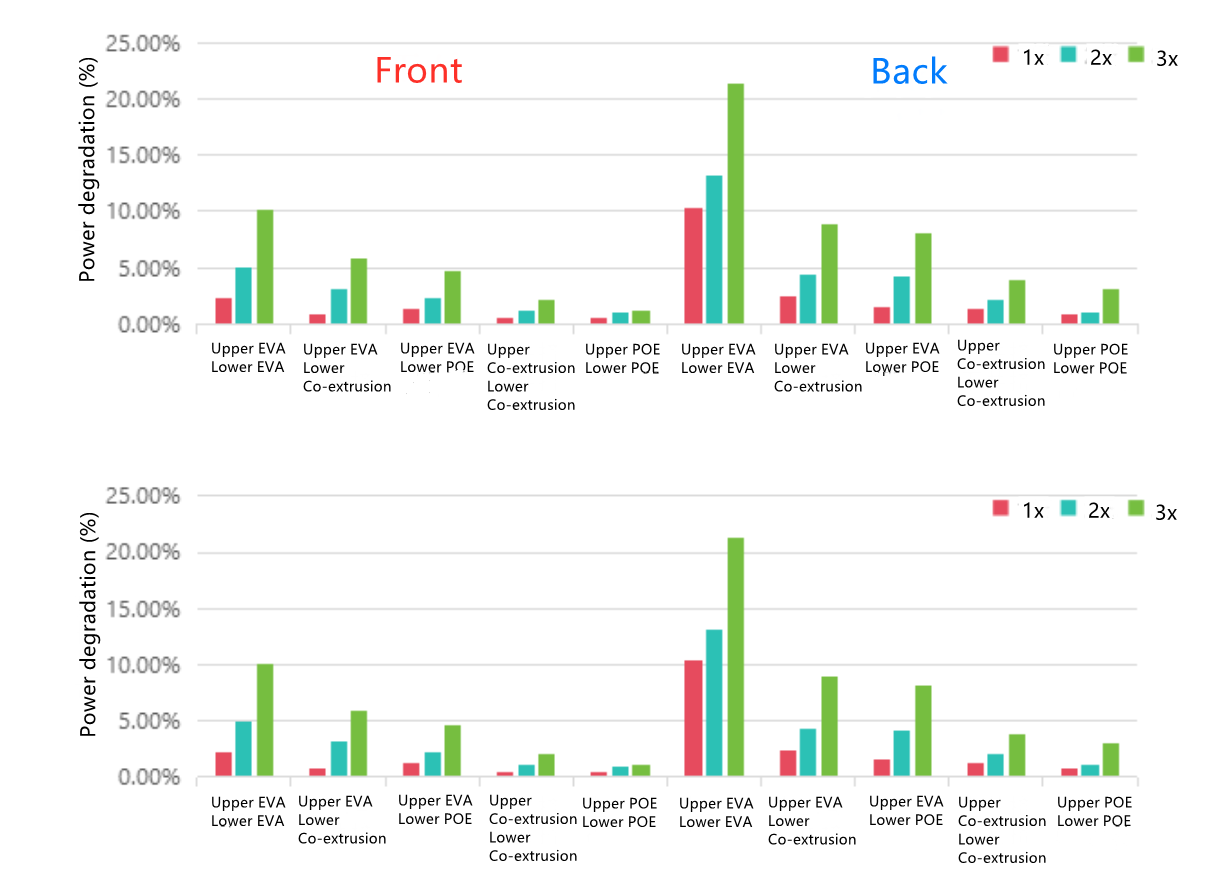

With TOPCon cells being susceptible to corrosive substances and aging when handling silver paste and grid lines, front-side POE encapsulation film has become a popular choice for module manufacturers. According to third-party experimental data, PID tests conducted with various encapsulation films revealed that modules using a combination of dual POE films exhibited the most robust PID resistance performance. The primary reason is that POE possesses high volume resistivity and low water permeability, which enhance PID resistance performance.

DAS Solar currently uses a dual POE encapsulation film for N-type modules. In the domain of photovoltaic modules with a lifespan exceeding 30 years, reliability remains a foremost concern for DAS Solar. It's important to emphasize that any improvements in efficiency must be accompanied by improvements in reliability during this ongoing transition from P-type to N-type technology. DAS Solar is committed to offer exceptional N-type product to deliver stable and reliable solutions to global customers.

浙公网安备33080302000236

浙公网安备33080302000236