POE allows TOPCon to more effectively utilize the benefits of cell technology

2023-11-04

PV modules have a service life of 25 years, and the reliability of the modules and the material plays an important role.

The crystalline silicon PV modules have been industrialized for over 40 years, and the technology and materials used today are completely different from 40 years ago. For example, the size of crystalline silicon cells has changed from the 5-inch chip (125mm) to the 188mm and 210mm, and the thickness of the cell has also decreased from the original 330 µm to around 150 µm, with a further downward trend.

The advancement of crystalline silicon cell technology has in turn made it more "brittle". As cells progress from aluminum backsheets to PERCs and N-type TOPCons, their efficiency continues to improve, which puts higher demands on the stability of packaging environment.

Under the pressure of cost, the PV backsheet has transformed from the original TPT and TPK structures to coated KPC, CPC, or even non-fluorinated backsheets. In this process of transformation, the backsheet's ability to protect the reliability of the modules has obviously decreased, and the pressure has suddenly applied to the packaging film.

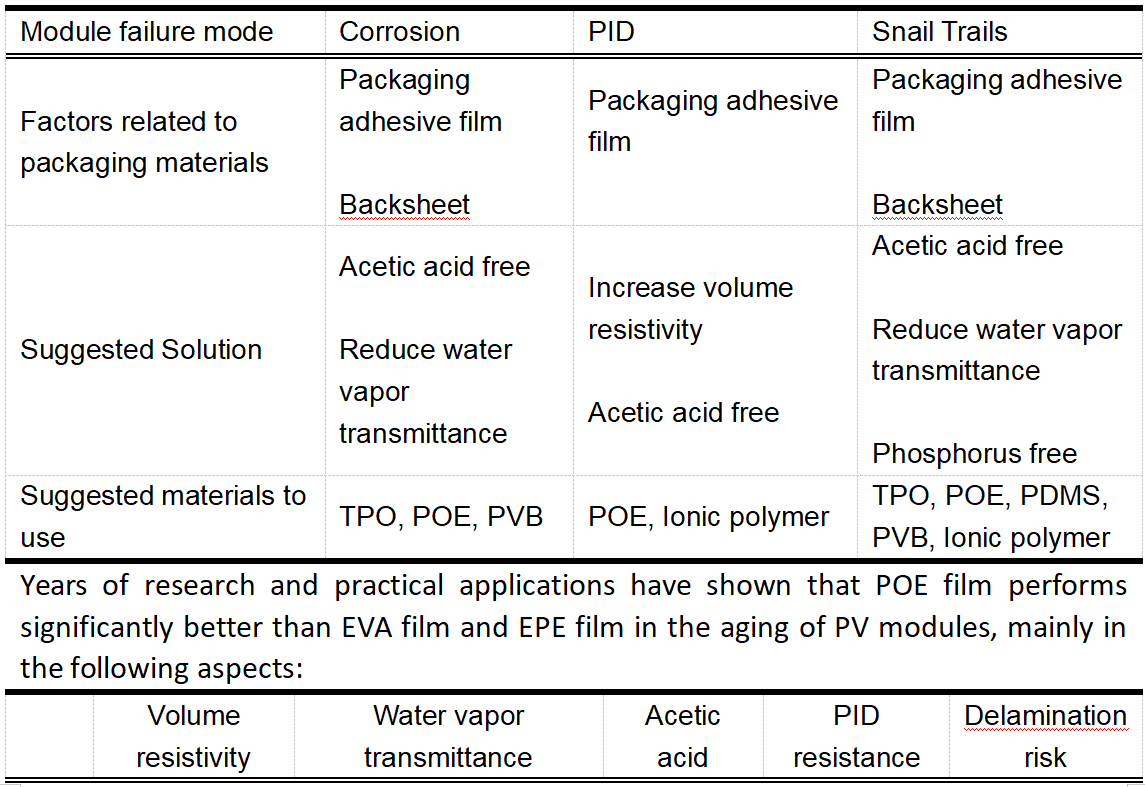

The polymer materials used in PV modules and their failure have been reviewed and analyzed by foreign scholars.

Nowadays, N-type TOPCon has become the mainstream cell technology, and the mass production power generation efficiency of TOPCon cells has exceeded 26% in 2023. At the same time, the silver paste on the front of TOPCon cells usually contains aluminum and lead, and selective electrodes are typically used to form good metallization contact. These technologies help to improve the power generation efficiency of the cell. However, the metalized contact interface containing aluminum silver paste is extremely sensitive to the chemical environment. The passivation layer SiNx and SiO2 on the cell surface will react with the acetic acid released by EVA and be slowly corroded, thereby reacting with water vapor entering from the outside. Acid and water erosion are the main causes of metallization contact failure in TOPCon cells. Therefore, the key to preserving the continuous and stable outdoor power generation of TOPCon cells is to prevent the infiltration of acid and water into the modules through the use of suitable packaging materials.

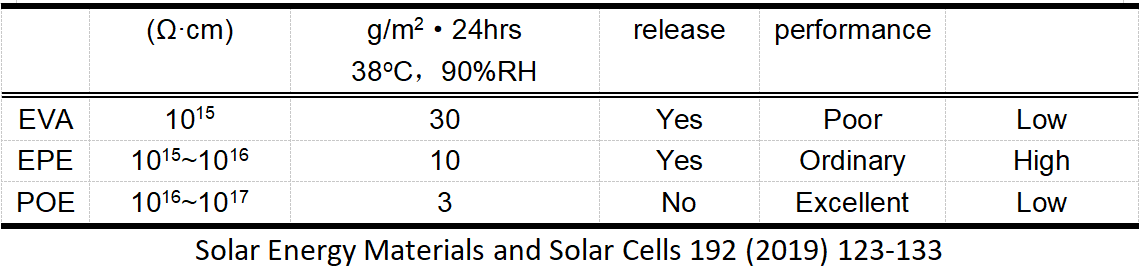

Currently, only POE adhesive film is the mainstream packaging material that can perfectly block the entry of acid and water into the modules. Firstly, the molecular structure of POE determines that it does not release any acidic substances and has low water permeability. However, due to the material limitations of EVA film and EPE film, they inevitably release acetic acid persistently inside the module and and they have high water permeability, which cannot be solved through other measures for single glass modules. This is also an important reason why major module manufacturers are firmly choosing to use POE adhesive film in the development of single glass TOPCon modules.

On the other hand, POE encapsulation adhesive film has a more than 10-year industrial history, and its reliability has been fully verified in both laboratory accelerated aging testing and outdoor practical application testing. In addition, top module manufacturers are no longer satisfied with the testing requirements of a single IEC in order to provide higher-quality products to their customers. The warranty period for modules is not limited to 25 years, and 30 or even 40 years have been suggested. This makes the internal reliability verification of module manufacturers more standardized and demanding. For instance, the import testing of DH2000 has become mainstream in the industry, and several companies are also conducting such tests on DH3000. The rapid development of cell technology and the demand for higher reliability make the selection of packaging adhesive films more inclined towards POE adhesive film products with better performance.

浙公网安备33080302000236

浙公网安备33080302000236